Technical Information

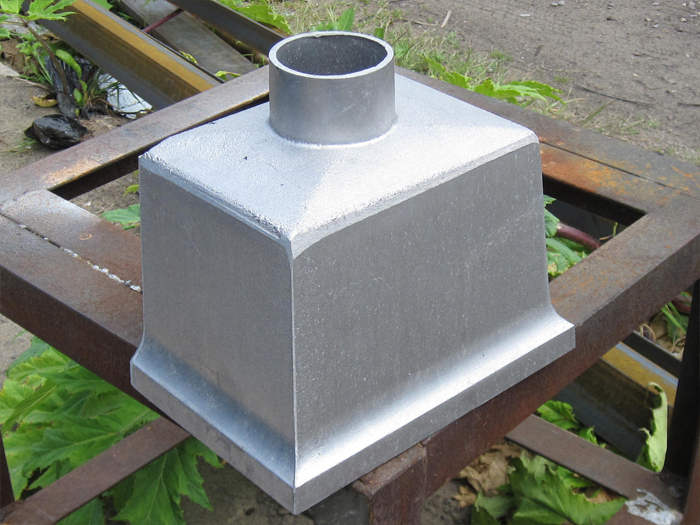

Marine Grade Cast Aluminium Gutters and Fittings

The marine environment is classed as within six miles of salt water or tidal estuary; however the salt can travel much further inland dependant on wind conditions. There have been cases where salt spray from roads has affected gutters over the winter of 2009/2010.

Up until now all manufacturers of cast aluminium gutters have used aluminium that contains significant Copper and Zinc, which is susceptible to electrolytic attack by salt water.

Any damage to the powder coating that allows salt water to penetrate through to the aluminium will, through electrolytic action, lift off the powder coating from the gutter and fittings.

Hall & Botterill Ltd in 2011 launched a full range of Marine Grade Cast Aluminium Gutters and Fittings to overcome these problems in the marine environment.

The marine grade aluminium is made from 100% recycled aluminium and is infinitely recyclable.

At Hall & Botterill we believe that Marine Grade Cast Aluminium Gutters and Fittings will become the industry standard, just as our slim fit range of cast aluminium pipe sockets did over the last twenty years.

It is through innovation and listening to our customers that has enabled Hall & Botterill to create the world’s largest range of Cast Aluminium Gutters and Fittings.

Aluminium Grades and Uses

LM4

MACHINABILITY – Reasonable machining properties. Liberal application of cutting lubricant and coolant.

CORROSION – Reasonable resistance, slight increase after heat treatment.

SUITABILITY – General Engineering.

LM6

MACHINABILITY – Low cutting speeds using carbide tipped tools and liberal use of cutting lubricant and coolant.

HEAT TREATMENT – Is of little industrial interest.

CORROSION – Excellent resistance under normal and extreme atmospheric conditions.

SUITABILITY – Wide range of uses.

LM25

MACHINABILITY – When heat treated has reasonable machining properties. Would recommend the use of high speed steel tools. Liberal use of cutting lubricant.

HEAT TREATMENT – Strength can be gained by heat-treating.

CORROSION – High resistance to corrosion by salt water and marine atmospheres.

SUITABILITY – General purpose, very high strength.

LM27

MACHINABILITY – Reasonable machining characteristics. Advise to use tungsten carbide tools and liberal use of cutting lubricant and coolant.

HEAT TREATMENT – Tensile properties may be increased by appropriate heat treatment.

CORROSION – Fairly good resistance to corrosion under normal atmospheric conditions.

SUITABILITY – General engineering.

![logo[1] Hall and Botterill](https://www.gutter.co.uk/wp-content/uploads/elementor/thumbs/logo1.png)